Industries

Some of the wonderful industries we work with.

Product quality begins upstream.

Bluewater provides the high-performance, reliability and accuracy needed to optimize your process.

INJECTION MOLDING

EXTRUSION & BLOW MOLDING

PLASTIC MANUFACTURING

MOLD MAKING

FOOD EQUIPMENT

LIFE SCIENCES

PLASTIC PROCESSING

PACKAGING

SEMICONDUCTOR PROCESSING

POWER GENERATION

DECORATING

RESEARCH & DEVELOPMENT

FOOD EQUIPMENT

LIFE SCIENCES

INJECTION MOLDING

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection molding can be performed with a host of materials mainly including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers.

We at Bluewater Heater provide products and solutions for the injection molding world such as heaters, sensors and controls

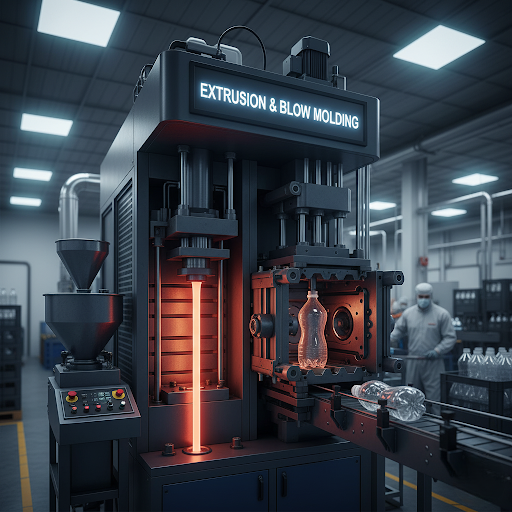

EXTRUSION & BLOW MOLDING

Product quality begins upstream. Regardless of your extrusion system, Watlow\’s family of thermal solutions provides the high-performance, reliability and accuracy needed to optimize your process.

Whether OEM or end-user, many of today\’s applications require process control data as well as history documentation to comply with various policies and regulations. Many processors proactively seek products that offer both traceability and product repeatability. Watlow\’s product solutions bridge the gap by providing evidence of overall product quality, assuring process repeatability and shortening overall startup time.

MOLD BUILDING/MAKING

Watlow has the heaters, sensors and controllers for your extrusion process:

The term moldmaker may also be used to describe workers employed in fabricating dies and metal moulds for use in injection moulding and die-casting, such as in the plastics, rubber or ceramics industries, in which case it is sometimes regarded as a variety of the trade of the toolmaker. The process of manufacturing molds is now often highly automated.

While much of the machining processes involved in mold making use computer-controlled equipment for the actual manufacturing of molds (particularly plastic and rubber injection and transfer). Moldmaking is still a highly skilled trade requiring expertise in manual machining, CNC machining, CNC wire EDM, CNC Ram EDM, surface grinding, hand polishing and more. Because of the high skill and intense labor involved much of the mold making in the US has been outsourced to low wage countries. The majority of plastic and rubber parts that are in existence today are made using injection or transfer molds- requiring a mold to be manufactured by a moldmaker.

FOOD EQUIPMENT

Whether it’s a cooking, warewashing or data communications challenge, your first-class foodservice equipment deserves an optimal thermal solution. Watlow has been heating up the foodservice equipment industry for decades as the leading thermal loop supplier.

NAFEM DP (Data Protocol) compliant controllers, superior heating and sensing solutions- whatever the need, Watlow is the single-source supplier able to cover applications from freezer to plate. We also provide superior manufacturing capabilities and global support.

Our know-how, innovation and resources have allowed us to provide exceptional food quality and customer satisfaction in equipment solutions worldwide.

- Char-broilers & Broilers

- Combi-Ovens

- Convection Ovens

- Conventional Ovens

- Conveyor Ovens

- Cook & Hold Ovens

- Cook-Serve Systems

- Deck & Pizza Ovens

- Electric Ranges

- Fryers-Open, Pressure & Flat Bottom

- Griddles & Grills

- Jacketed Kettles

- Pasta Cookers

- Proofer Ovens

- Rotisserie Ovens and Cabinets

- Smokers

- Steamers

- Toasters

Heated Preparation, Serving & Display Equipment

Coffee Brewers & Roasters

Cooker/Warmers and Hot Wells

Heated Display and Deli Cases

Heated Merchandising Cabinets

Hot Plates

Rethermalizers

Warmers – Countertop, Drawers, Drop-In, Pass-Thorough

Storage & Handling Equipment

Blast Chillers

Cook-Chill Systems

Heated Meal Delivery Systems

Hot Holding Cabinets

Ice Machines

Proofer Cabinets

Refrigerators & Freezers

Warming Cabinets

Sanitation & Safety Equipment

Lower operational costs

Increased efficiency

Improved food safety and quality

Equipment maintenance and diagnostics

Watlow is a proud member of the North American Association of Food Equipment Manufacturers. NAFEM represents approximately 700 companies throughout the United States, Canada and Mexico that manufacture commercial foodservice equipment and supplies. Click here to learn more about NAFEM.

Plastic Processing

Downtime costs you money. Unreliable products and vendors can stress you out. Let us ease your pain! For over a decade, Bluewater Heater has been a preferred supplier of electric process heaters, thermocouples, temperature controls, power controls and process heater systems. We supply to processing industry end users, process equipment OEMs and system integrators, as well as E&Cs. Our performance goal is to lighten your stress and workloads through:

Ultra-Fast Stock and Stock Mod Product Delivery

High Performance Custom Designed Heaters and Control Systems

Quick Response on Quotes and Orders

Outstanding Technical and Applications Support

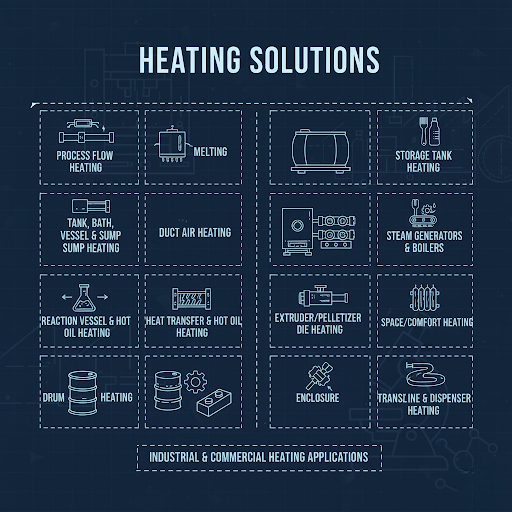

Applications

- Process Flow Heating

- Tank, Bath

- Vessel & Sump Heating

- Duct Air Heating

- Reaction Vessel & Chamber Heating

- Heat Transfer & Hot Oil Heating

- Drum Heating

- Storage Tank Heating

- Steam Generators & Boilers

- Extruder/Pelletizer

- Barrel & Die Heating

- Space/Comfort Heating

- Enclosure Heating

- Transfer Line & Dispenser Heating